Galal carried out the numerical analysis to upgrade the container terminal with an open berth on pile type structure in Egypt. To enhance these quay walls, some methods were adopted in which they focused on using jet grouting and micro-piles to increase bearing capacity and front water depth of berth. summarized the main issues involved and experiences in geotechnical design for upgrading six quay walls to meet new demands in Italy.

Oung and Brassinga discussed widely the risks of upgrading the existing quay walls such as deepening in front of quay walls and increasing the loads on the quay surface. conducted a basic study on wharf deepening for the improvement of harbor facilities. Examples of projects in several countries (Europe and Africa) where different types of existing quay walls were strengthened and deepened illustrate the guidelines. proposed some general guidelines for an integrated design and construction approach, combining risk fault tree analyses, robust and flexible design, construction methods and monitoring methods. Elsken and Bols indicated that combining the techniques of the very high-pressure grouting, installation of ground anchors and drains had already proven to be an economical and technical solution for deepening the quay walls. Regarding this issue, many case histories about the deepening and upgrading of the existing quay walls have been reported in the literature.

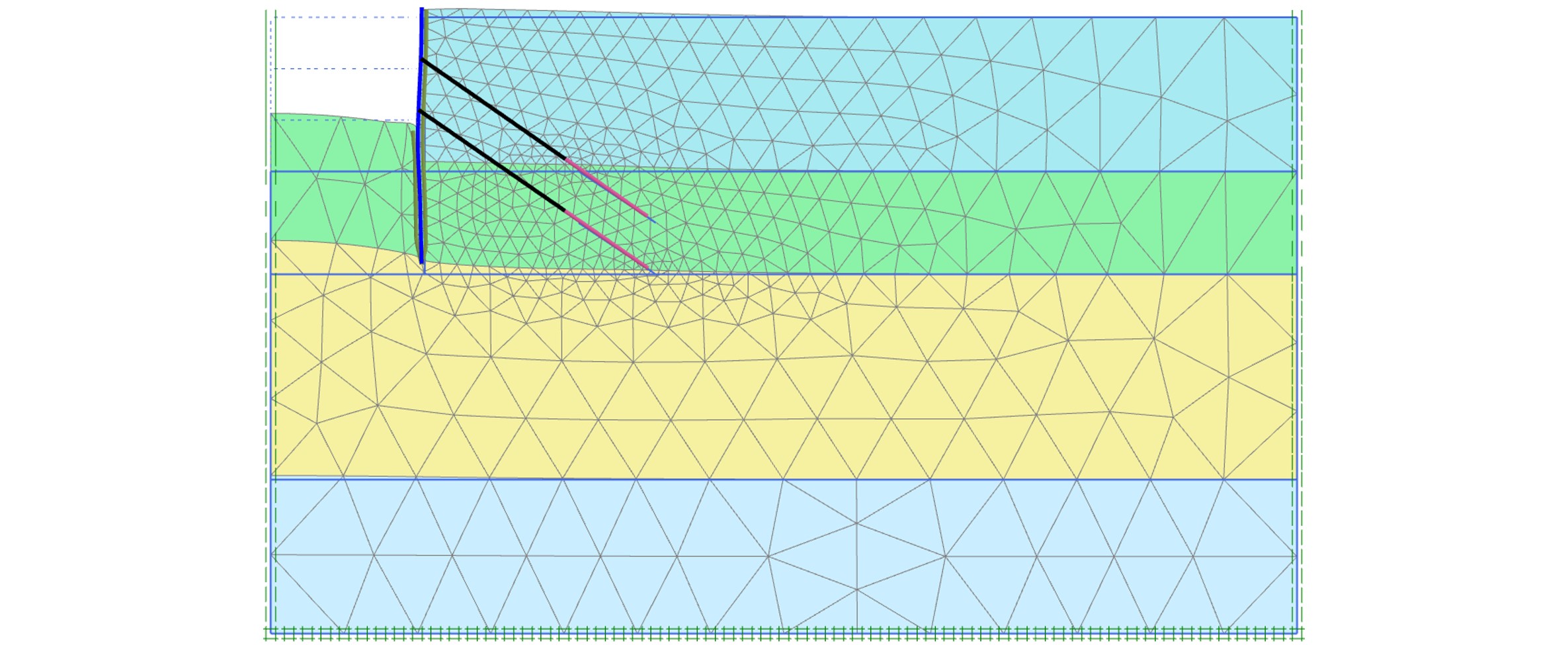

Thus, upgrading the existing quay walls are giving great challenging for engineers and researchers. However, due to the high costs and the environmental boundaries, the complete demolition of these existing quay walls and replacing them with new structures are not preferred. However, many quay walls have been used for a long time becoming out-date and cannot meet current demands. Therefore, the deep-water ports become more and more necessary to accommodate these ships. Nowadays, the demand for cargo transportation via waterways are rising significantly with the rapid increase of the large tonnage ships. The analysis also indicates that when the Hardening Soil (HS) model is applied, the displacement of the quay wall is higher than that of the Mohr–Coulomb soil (MC) model. The results demonstrate that after upgrading, the maximum contact stress between caisson and rubble mound increases sharply, but the stress at the bottom of grouted rubble does not change in comparison prior to innovation. In addition, the numerical analysis is performed by the Finite Element Method (FEM) program (PLAXIS 2D) to expect the behavior of the quay wall and grouted rubble.

Based on the examination of stability and construction feasibility, the reasonable geometry and area of grouted rubble can be selected. Various cases with different shapes and dimensions are proposed to optimize the grouted area. To deepen the water depth, a special grout type is ejected to solidify the rubble mound under the caisson toe, then excavating a part of the rubble placed in front of the caisson to the designed level. Therefore, the main goal of this study is to enhance the performance of these quay walls by increasing the front water depth. However, many of the existing quay walls constructed in the past are becoming obsolete. Caisson type gravity quay wall is a common structure used in the coastal regions.

0 kommentar(er)

0 kommentar(er)